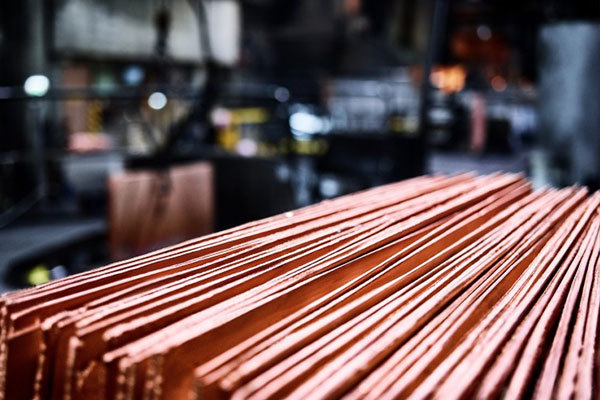

Production of galvanized steel rolls

Time:

Oct 25,2024

In a bustling steel mill, workers are hard at work producing galvanized steel coils. The process starts with raw steel coils being fed into a hot dip galvanizing line. These coils are cleaned and pre-treated to ensure a smooth surface for the zinc coating to adhere to.

In a bustling steel mill, workers are hard at work producing galvanized steel coils. The process starts with raw steel coils being fed into a hot dip galvanizing line. These coils are cleaned and pre-treated to ensure a smooth surface for the zinc coating to adhere to.

Once the coils are prepped, they are then submerged into a bath of molten zinc at high temperatures. This process, known as hot-dipping, ensures that the steel is completely coated with a layer of zinc, providing excellent corrosion resistance and durability.

After the zinc coating has been applied, the coils are cooled and inspected for quality control. Any defects or imperfections are quickly identified and rectified before the coils are sent off for further processing.

The galvanized steel coils are then either cut into sheets or wound into coils, ready to be shipped out to various industries for a wide range of applications. From construction to automotive manufacturing, galvanized steel is a versatile and reliable material that is in high demand.

As the demand for galvanized steel continues to rise, steel mills are working tirelessly to meet the needs of their customers. With their dedication to quality and efficiency, these mills are ensuring that the production of galvanized steel coils remains a vital part of the global steel industry.